- Orodjarstvo Krizaj

- Responsive

- Posted by

Desired outcome

Our challenge is to diversify the production and service offerings of our small boutique die casting tool manufacturing company - https://www.orodjarstvo-krizaj.si/. We are looking to expand beyond our current market focus and explore new opportunities in a rapidly evolving industry landscape. This involves identifying potential new directions for growth that align with our capabilities and market trends. The challenge requires teams to initially propose a broad range of diversification ideas and then delve into a detailed analysis of the most promising 2-3 opportunities. The goal is to develop actionable strategies that can help us adapt to changing market demands, integrate innovative technologies, and ensure sustainable growth in a competitive environment.

Initial Problem Description

We are a small boutique manufacturer of die casting tools - https://www.orodjarstvo-krizaj.si/

Our challenge is to find opportunities to diversify our production and to analyze some of these opportunities in detail. As a first step, we expect the groups to come up with a quick, initial, rough list of possible directions for expanding our production and service offering. In the next step, we will select 2-3 directions from the list of directions proposed by you and ask you to analyze the selected 2-3 business opportunities in detail.

Context

Our company is active in the specialized field of die casting tool manufacturing and primarily serves niche markets in the automotive and industrial machinery sectors. The die casting industry is highly competitive and subject to fluctuations in demand depending on global economic trends, technological advances and changing customer needs.

Recently, we have observed a trend towards more customized, small-scale production runs, and a growing demand for sustainable and innovative materials for die casting processes. In addition, the emergence of new technologies such as 3D printing and advanced CNC machining is changing the landscape of tool manufacturing and presents both challenges and opportunities for our business.

In this context, our challenge is to adapt and expand our production capacity to meet these evolving market demands. We need to explore new sectors or technologies where our expertise in die casting tool manufacturing can be applied or adapted. This could include diversifying into related areas, such as precision tooling for emerging industries, or expanding our service offering to include more comprehensive solutions for our customers, such as design consultancy or post-production services.

The goal is to find new business opportunities that align with market trends and our company's core competencies to ensure our long-term sustainability and growth in a rapidly changing industry.

Connection to cross-cutting areas

Our challenge is linked to the core principles of Industry 4.0, which emphasize digitalization, interconnectivity, automation and data-driven decision-making in manufacturing processes. Here are a few possible connections for your ideation process.

Digitalization and smart manufacturing: Exploring opportunities that utilize digital technologies to improve our manufacturing processes. This includes integrating advanced software for design, simulation and production planning, which can open up new production opportunities and improve efficiency and adaptability.

Data analytics and AI: Using data analytics and AI for predictive maintenance, quality control and market analysis.

IoT and connectivity: Streamlining operations and enabling real-time monitoring and control of manufacturing processes.

Sustainability and new materials: researching sustainable practices and materials in die casting, adapting to environmental standards and new market requirements for environmentally friendly production.

Customization and flexibility: Individual solutions and flexible production options. By using technologies such as 3D printing alongside traditional (or advanced or boutique) die casting, we can meet specialized production requirements in small quantities and delve deep into know-how of die casting processes.

Input

We have identified several industry trends and scenarios that can serve as a starting point for student exploration and analysis. These include:

Increasing demand for customization: there is an increasing trend towards personalized production and small batch production in various sectors. This demand for customization offers us the opportunity to adapt our manufacturing processes and offer more specialized products.

Sustainability and environmentally friendly practices: The global shift towards sustainability is influencing the manufacturing industry. There is an increasing demand for environmentally friendly materials and energy efficient production processes. Research into environmentally friendly innovations in die casting could open up new market opportunities.

Technological advances: The integration of technologies such as the latest die casting innovations, 3D printing, advanced robotics and artificial intelligence into manufacturing processes is transforming our industry. Understanding how these technologies can be used in die casting tooling could help identify new service offerings or process improvements.

Shifts in global supply chains: Recent shifts in global supply chains, due in part to geopolitical factors and the COVID-19 pandemic, have highlighted the need for more resilient and adaptable manufacturing strategies. Exploring how to capitalize on these changes could prove beneficial.

Emerging markets: Identifying and targeting emerging markets, such as the renewable energy or advanced electronics sectors, where die casting tools may be in demand, represents a growth opportunity.

We encourage students to use these trends and scenarios as the basis for their research. However, they should also feel free to research beyond these areas, as part of the challenge is to identify untapped opportunities that we may not have considered.

Expectations

We expect the solution to evolve in a direction that is both innovative and practical, in line with our company's capabilities and current market trends. In particular, we expect solutions that provide actionable strategies for diversifying our manufacturing and service offerings, with a focus on integrating advanced manufacturing technologies and responding to new market demands.

In addition to the tangible solutions they deliver, we have other expectations of the team:

Creative thinking: we expect the team to think creatively and out of the box. Innovative ideas that challenge the status quo and suggest new avenues for growth are highly valued.

Market and feasibility analysis: While creativity is important, we also expect solutions to be based on practical considerations. The team should conduct a thorough market and feasibility analysis to ensure that the proposed solutions are viable and sustainable in the long term.

Technical understanding: A good understanding of the technical aspects of die casting tooling manufacturing and associated technologies is important. This helps to develop solutions that are technically sound and feasible.

Consideration of sustainability: Proposals should consider the sustainability aspect, both in terms of environmental impact and the long-term viability of the business.

Presentation and documentation: A clear and professional presentation of the results and proposals is expected. It is also important to have well-organized documentation that we can refer to and rely on after the project.

Ultimately, we are looking for a mix of innovative thinking, practical solutions and a deep understanding of the challenges and opportunities in our industry. The team's ability to deliver a well-researched, clearly articulated and actionable strategy for diversification will be key to the success of this project

Desired Team Profile

The expert opinion we are looking for is as follows:

Mechanical or industrial engineering: Individuals with a background in mechanical or industrial engineering will bring essential knowledge of manufacturing processes, design principles and an understanding of die casting technologies.

Business and market analysis: Team members with business or economics knowledge are highly beneficial for conducting market analysis, feasibility studies and developing business strategies. This includes understanding market trends, customer needs and competitive situations.

Sustainability and environmental sciences: Given the increasing importance of environmentally friendly practices, expertise in sustainability and environmental science would be beneficial for researching sustainable aspects of manufacturing processes and materials.

Data science and analytics: Individuals with expertise in data science and analytics would be critical for data-driven decision making, market analysis and potentially exploring the applications of AI and machine learning in manufacturing processes.

Innovation and design thinking: Team members with a background in innovation management or design thinking would help to find creative solutions, solve problems and think outside the box.

Technology and automation: Expertise in modern manufacturing technologies such as advanced die casting technologies and latest achievements, 3D printing, robotics and automation in line with Industry 4.0 principles would be beneficial.

We are open to the inclusion of members with other relevant skills and backgrounds who can make a unique contribution to solving the challenge. A balance of technical knowledge, business acumen, creative thinking and practical implementation skills is crucial.

Additional Information

Competitive landscape: The die casting tool manufacturing sector is highly competitive, with several large companies dominating the market. Nevertheless, there are niches and opportunities for boutique manufacturers like us, especially in specialized or customized production areas.

Technological trends: The industry is increasingly relying on advanced technologies such as automation, 3D printing and AI-driven design and manufacturing processes. Understanding these trends is critical to proposing viable diversification strategies.

Economic factors: Current economic factors, including fluctuations in raw material costs and the impact of global trade policies, have a direct impact on our business and market opportunities. Insights into these factors should be considered in the analysis.

Focus on sustainability: There is an increasing emphasis on sustainability in manufacturing, which has an impact on customer preferences and regulatory requirements. This includes the use of environmentally friendly materials and energy-efficient processes.

Customer base and demand patterns: Our primary customer base has historically been in the automotive and industrial machinery sectors. However, changing demand patterns, including the rise of electric vehicles and renewable energy, are transforming these markets.

Regulatory environment: Understanding the regulatory environment in which we operate, including new or impending changes, is important to ensure that proposed solutions are feasible and compliant.

Related Keywords

About Orodjarstvo Krizaj

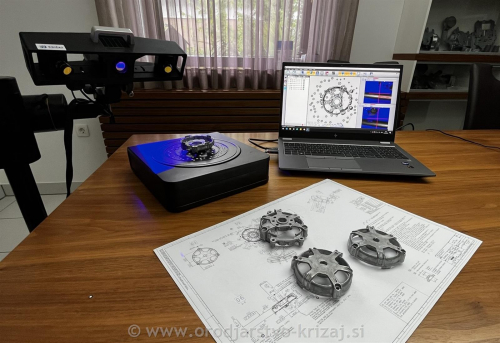

Specialist in tool manufacturing for aluminum die casting, established in 1982. A family-owned Slovenian business with a dedicated team of professionals. Expertise in design, engineering, machining, and simulations. Offering a wide range of services including R&D, prototyping, and small batch production.

You need to sign up to apply to this challenge and submit a motivation letter!

Learn more about the topics and find team members!

Help

Need help submitting your proposal or have questions regarding this Open Innovation Challenge?

Contact support