Desired outcome

We need an app for receiving and translating data from the metal forming tools sensors into the decision makers language or other form for presenting the results (temperature, force).

Initial Problem Description

We want to lower the consumption of energy and materials at our partners in serial production through lowering their production ejection by ensuring them with cruical data for stabile production. We will incorporate temperature and force sensors into the tool and connect them with external device (wifi) to the existing or non existing MES system of the customer.

Context

Our chalenge is to lower the production ejection that appers when the temperature of the tooling is too high by sending alarms to the production manager or operator by means of smart devices or e-mails to act accordinly (stop, cool-down).

Also we need information from sensors about the force equilibrium in the tools.

Connection to cross-cutting areas

Our challenge is connected directly to the areas of Circularity, General sustainability, Industry 4.0 and Digitalisation through lowering CO2 emissions of the production of temperature exchanger significantly, by digitalization of stamping parameters, graphical showing of the forming procces in real time and so on.

Input

We will need a new application and new instructions for customers use of the application, where application will need to work on smart phones, tablets and computers through wi-fi 5G connection. Application will have to save data about running the tool from the start of the tool cycle to its end (counting hubs, graphical showing of the temperatures and forces in the tools with "red", "green" and "yellow" colors for representing status of the tool accordinly.

Expectations

We expect to get the insights from other industries that have already gone through this change transformation in order to truly find out what is being expected from our side and what is possible to do on the other side, when programming our application to connect to temperature and force sensors in the tools.

Desired Team Profile

We would like to have somebody or team with toolmaking or technical skills or experinces in the field of metal parts production that doesn't have problems to understand decision makers or managers thinking. We are also new to this field, connecting senzors to external device communicating with MES system of the customer.

Additional Information

Ther are already existing commercial applications for connecting IOT devices to a working MES system (Panda, TomPIT). But we would like our own application to offer to our customers that wil ensure that the guarantee period and maximum stamping volume is not in any way exceeded, also we would like to offer our customers predicted servicing upon real data, to lower their botlleneck losses.

Related Keywords

About LIBELA ORODJA, IZDELOVANJE ORODIJ IN PERFORIRANJE PLOCEVINE, D.O.O., CELJE

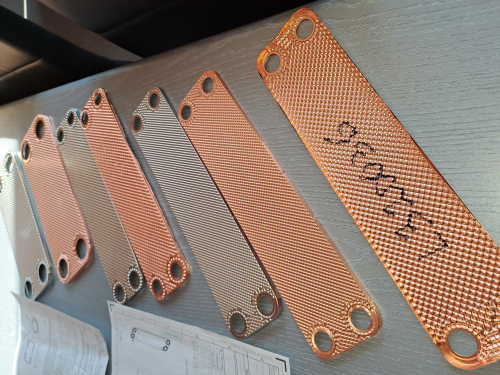

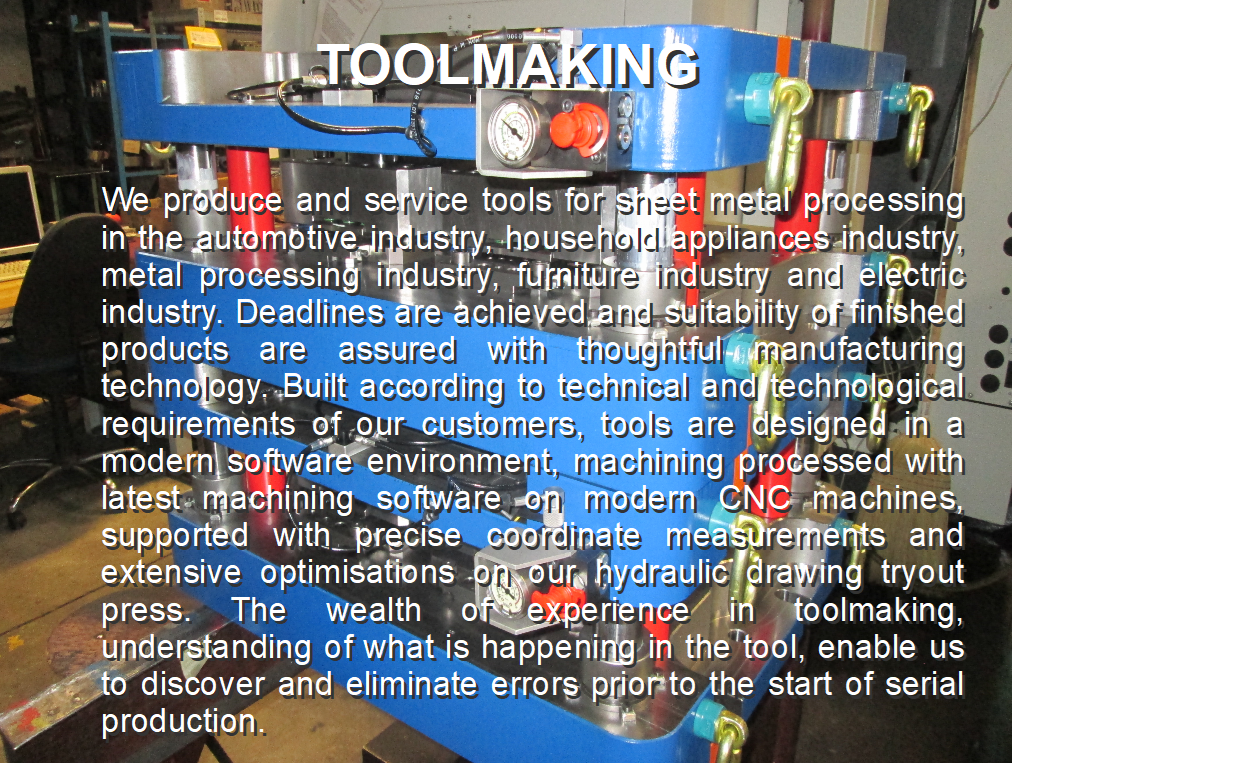

Libela orodja develops, manufactures and maintains tools for the processing of sheet metal, plastic and pressure jet, carries out automation of manufacturing operations and perforation of sheet metal. By investing in hardware and employee knowledge, through the use of informational technology and management standardization, it ensures high quality of its products and services, as well as the complete satisfaction of its customers.

You need to sign up to apply to this challenge and submit a motivation letter!

Learn more about the topics and find team members!

Help

Need help submitting your proposal or have questions regarding this Open Innovation Challenge?

Contact support