- DigitaLLeather doo

- Responsive

- Posted by

Desired outcome

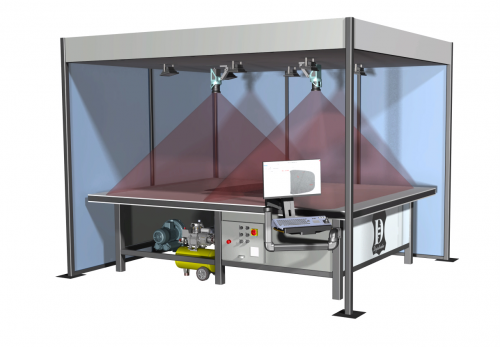

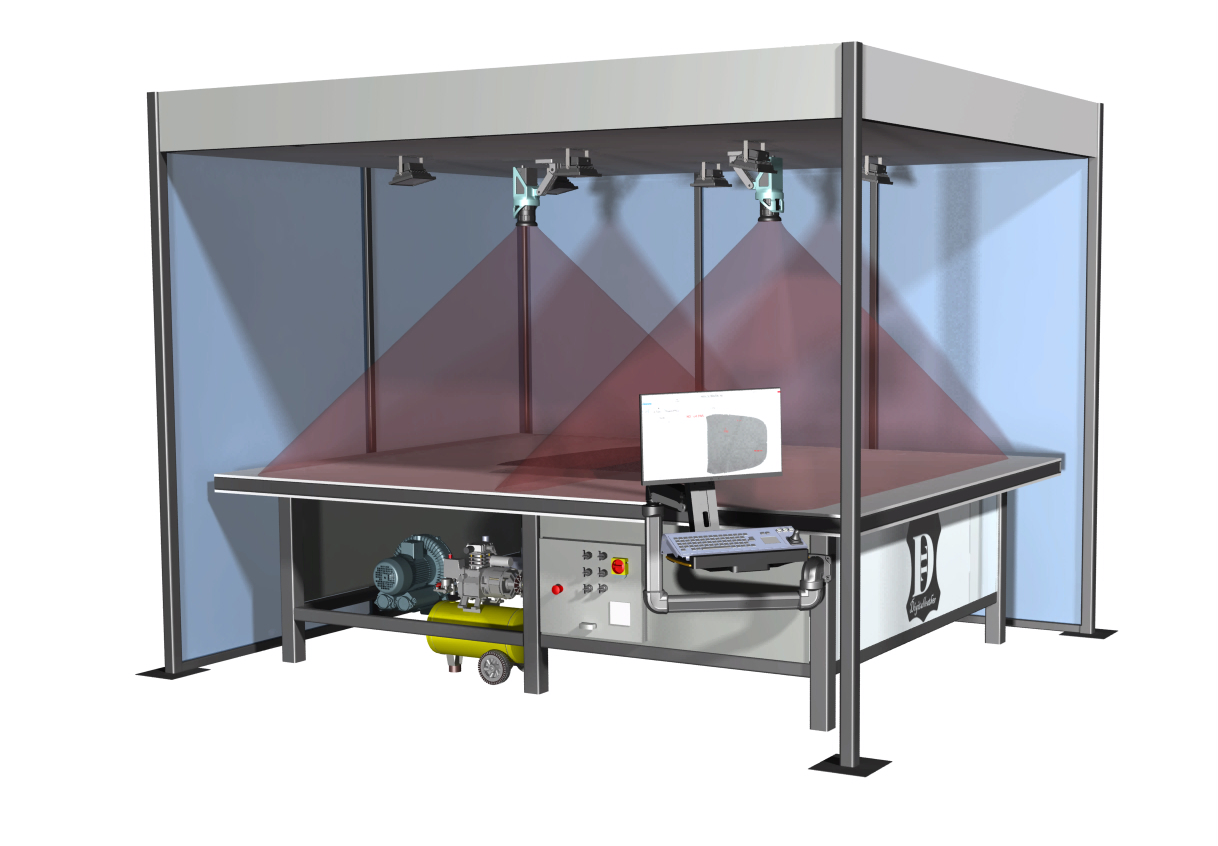

We are developing a technical solution combining hardware and software. The hardware will consist of a vacuum table for industrial leather hide, intended to flatten the leather and prepare it for photography. A fully enclosed chamber will be installed on the vacuum table, housing lighting of appropriate intensity, as well as a system for capturing photography, which practitioners will develop as part of this challenge. The software will include an API for detecting, classifying, and measuring defects on industrial leather using artificial intelligence, along with a Product Data Management API. To ensure adequate input for training the artificial intelligence algorithms (Computer Vision), it is necessary to select suitable industrial equipment for capturing 2D photographs of leather hide.

Initial Problem Description

The problem we aim to solve with this challenge is the selection of an appropriate method and technology to photography/scan industrial leather hide. The vacuum table on which the industrial leather hide is placed measures 3000x3000mm, and the required image quality is a minimum of 4K (3840x2160) in 2D format. It should be considered that the size of industrial cowhide will vary between 3.5-6.5 m2. Additionally, LED and UV lighting will be used within the chamber at various angles from 0-90 degrees, directed towards the surface of the industrial leather hide. Therefore, the problem we have is selecting an appropriate system that will allow us to capture suitable 2D images of the leather, satisfying all the specified parameters.

Context

The problem arises in the context of implementing a subsystem, an innovative technical solution we are developing for the leather industry. Our goal is to develop a technical solution that will enable us to detect defects on industrial leather hide before the cutting process, aiming to optimize utilization and reduce waste leather. The subsystem that practitioners are expected to develop is part of the hardware solution and will serve as input for training artificial intelligence algorithms. The technical solution will be applied in the leather industry, primarily in the production of mass-produced items, such as leather upholstery for the automotive industry, for example.

Connection to cross-cutting areas

Our solution is linked to circularity, Industry 4.0, and process digitalization because the ultimate goal is to reduce waste leather and increase utilization through the application of artificial intelligence (Machine Learning and Computer Vision). We will transform the current traditional and manual process of leather hide defect detection with a fully digitized process, with optimal utilization of material resources.

Input

Currently, there is no existing digitalized solution worldwide for detection of industrial leather defects, so we can’t give you additional inputs. We should consider similar applications on objects with surface areas ranging from 3.5 to 6.5m², such as metal sheets. Some of the proposed technologies can be fixed like 2D camera/s or movable like CNC carriers, laser technologies for scanning, drones, etc.

Expectations

Three key outputs we expect from the team are:

The quality of the 2D photography should be a minimum of 4K resolution (3840x2160) of the 3000x3000mm surface.

The team should aim to fit within a budget of €10,000 (attach specifications and bills of material with costs and useful links). Consider that all equipment used should be suitable for serial production in industrial conditions, meaning the equipment lifecycle needs to be accounted for.

The team should aim to integrate the entire process of digitizing industrial leather and obtaining 2D photographs within a 120-second cycle time.

Important note: The team must choose a technology that will capture a 2D photograph in one piece; combining multiple photography into one is not acceptable.

Desired Team Profile

It would be best to assemble a multidisciplinary team to address this problem. Some specific knowledge areas the team should possess include:

1. Understanding of photography and image acquisition technology for the quality of 2D photography as input into Artificial Intelligence.

2. Knowledge of the industry and industrial conditions (experience in the leather industry or automotive industry is a significant plus) as the solution needs to be tailored to industrial conditions.

3. Understanding of automation and digitalization technologies in case the team opts for a movable solution.

4. It is desirable for the team to have a member who understands the application of Machine Learning and Computer Vision technologies to emphasize the importance of input and provide guidance on which direction to consider when choosing technologies.

Additional Information

We suggest that the team begins by researching existing solutions on the market, if any, and scientific studies conducted on this topic. The team could utilize the Google Scholar platform for academic papers using keywords such as Industrial Leather, Defect Detection, Artificial Intelligence, Computer Vision, etc. If this doesn't yield results, the team should consider applying these technologies to solve other problems, such as defect detection on metal surfaces of the specified dimensions (3000x3000mm). If the team lacks an expert in photography, they should thoroughly study photography and understand the minimal quality conditions required for 2D photography.

Related Keywords

About DigitaLLeather doo

We are an innovative startup based in Kragujevac, founded in 2021 by the Innovation Fund of the Republic of Serbia. Our goal is the development of a technical solution for detecting defects in industrial leather using artificial intelligence. Since the beginning of 2023, we have expanded our operations from innovation to industry.

Our main focus is on developing technical solutions for the industry based on the application of programming, smart technologies, and artificial intelligence to address various industrial problems and challenges.

Our vision is to actively participate and significantly contribute to the development of the industry in the Republic of Serbia towards the Industry 4.0 transition, which is a popular trend worldwide. In addition to technical and technological development, we also provide consulting services to enhance business operations in the industry and other organizations. Our richest experience in providing these services lies in collaboration with the automotive and military industries.

You need to sign up to apply to this challenge and submit a motivation letter!

Learn more about the topics and find team members!

Help

Need help submitting your proposal or have questions regarding this Open Innovation Challenge?

Contact support