- Orodjarstvo Krizaj

- Responsive

- Posted by

Desired outcome

We invite you to propose innovative product ideas that leverage the expertise of a consortium of small and progressive companies specializing in advanced manufacturing, precision machining, mechatronics, engineering and aluminum die casting. The selected idea will be supported through to the virtual prototyping stage and potentially** to full development into a market-ready product.

** If the idea and virtual prototype are of further interest to our consortium at the end of the INDUSAC Challenge project phase, we would co-fund the development of a physical prototype and involve interested students to continue working with us until the actual products are sold (if all R&D phases show a strong sales potential of the product).

Initial Problem Description

We are looking for innovative product ideas that solve unique end-customer or business customer problems in a variety of industries, particularly (but not limited to) die casting, mountain farming, extreme infrastructure, extreme habitats, mechatronics, engineering, and advanced manufacturing.

Student teams are encouraged to utilize the expertise and resources of our consortium to develop and propose solutions that can be turned into virtual (and later physical) prototypes. The goal is to find a business-to-business or business-to-customer product idea with great potential for market success and practical application.

We are a consortium of several small and progressive companies, legally represented by Orodjarstvo Krizaj:

Lavrih: Manufacturer of advanced mountain farming equipment, owner of patented solutions for the unique challenges of mountain farming.

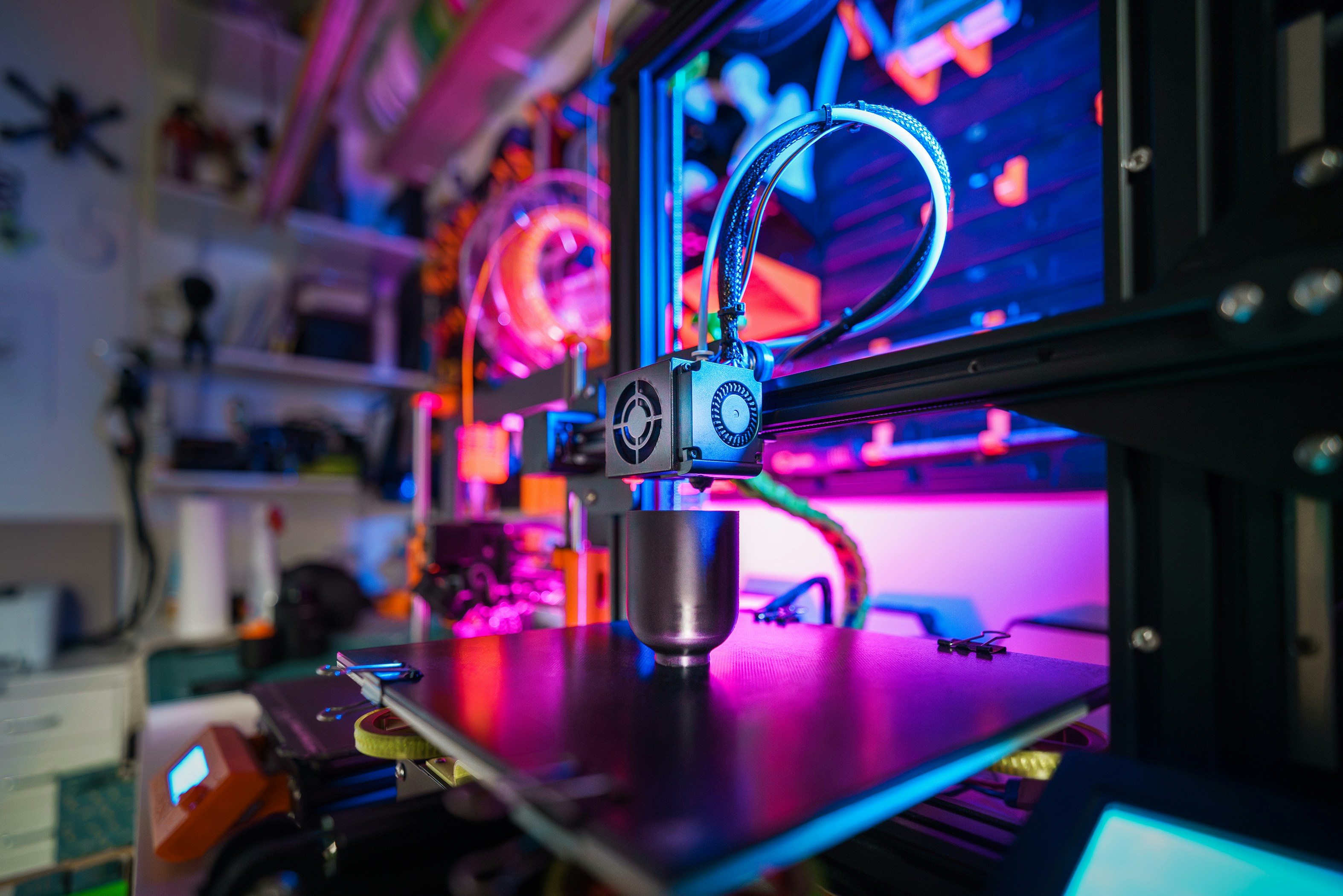

Orodjarstvo Krizaj: Experts in aluminum die casting tools, precision machining and related solutions.

Marcheta: Solution provider in the field of mechatronics and mechanical engineering, known for projects such as telecommunication towers and complex production and transportation facilities.

Krizaj Metal: CNC machining of metal products of all levels of complexity.

Context

This challenge stems from the need for breakthrough solutions in industries such as (but not limited to) mountain farming, extreme infrastructure, extreme habitats and advanced manufacturing. Recently taken over by a new generation of young engineers and supported by several senior experts, our companies have expertise in solving complex problems and delivering high quality, innovative products. The challenge is designed to harness the creativity and fresh perspectives of students to develop and commercialize new product ideas that build on and expand our current expertise.

Connection to cross-cutting areas

Industry 4.0: Integration of digital technologies in product development and manufacturing.

Digitalization: Use of digital tools and platforms to create virtual prototypes and streamline development.

Circularity: Ideas that relate to sustainable and circular production processes.

General sustainability: Solutions that consider the principles of environmental sustainability and maximize resource efficiency.

Input

With our INDUSAC challenge, we want to offer students the opportunity to propose any idea they want to develop and use our companies' expertise to turn it into a virtual prototype. Our consortium will then select the most promising idea(s) and support the team(s) to develop it in detail and create a virtual prototype.

If the idea and virtual prototype are of further interest to our consortium at the end of the INDUSAC Challenge project phase, we would co-fund the development of a physical prototype and involve interested students to continue working with us until the actual products are sold (if all research and development phases show a strong sales potential of the product).

Expectations

We expect students to come up with innovative product ideas that can be practically developed into virtual prototypes. The selected idea(s) will be supported by our companies to refine the first prototype and, if feasible, move on to the development of a physical prototype at the end of the INDUSAC Challenge project phase. We expect solutions that have a clear path to marketability and a high sales potential.

We offer the resources, know-how and global connections of our companies for the development and production of ideas and prototypes. Apart from our technical expertise, there are no limits to your ideas. To give you a feel for this, here are some of the possible leads and directions in which your ideas can test the waters:

RENEWABLE ENERGY: Products that support solar, wind or other renewable energy sources, improve efficiency or reduce costs for energy producers and consumers.

HEALTHCARE AND MEDICAL DEVICES: Innovations in medical devices or healthcare solutions that improve patient care, diagnostics or treatment efficiency.

AGRICULTURE AND SMART FARMING: Tools and equipment for precision agriculture that improve crop yields and farmers' sustainability practices.

SMART CITIES AND INFRASTRUCTURE: Solutions for urban development, including smart infrastructure, transportation and public services to improve living standards in cities.

ENTERTAINMENT ELECTRONICS: Advanced gadgets or household appliances that offer new functions or improve user-friendliness.

AUTOMOTIVE AND ELECTRIC VEHICLES: Components or systems that improve the performance, safety or sustainability of all types of vehicles.

AEROSPACE: Innovations that improve the performance, safety or cost-effectiveness of aerospace technologies.

ROBOTICS AND AUTOMATION: Products that facilitate automation in manufacturing, logistics or other industries, increase efficiency and reduce labor costs.

ET CETERA: Anything you would like to explore.

Desired Team Profile

Teams should ideally have a background in mechanical engineering, industrial design, materials science or related fields. Previous experience with CAD, prototyping and market analysis is highly desirable.

Collaboration between the team and your professors and/or teaching assistants and/or lab personnel (by prior arrangement) is also desirable, but not essential.

Additional Information

Participants should be aware of the competitive landscape in advanced manufacturing and engineering. Please keep in mind that if you are selected and we collaborate on a potential joint R&D journey, information about current market trends, competitor products and potential technological advances will need to be carefully gathered to support the development of the selected ideas. The more you look into all these things, the greater the chances that we can work together until the actual product is made.

Related Keywords

About Orodjarstvo Krizaj

Specialist in tool manufacturing for aluminum die casting, established in 1982. A family-owned Slovenian business with a dedicated team of professionals. Expertise in design, engineering, machining, and simulations. Offering a wide range of services including R&D, prototyping, and small batch production.

You need to sign up to apply to this challenge and submit a motivation letter!

Learn more about the topics and find team members!

Help

Need help submitting your proposal or have questions regarding this Open Innovation Challenge?

Contact support