Desired outcome

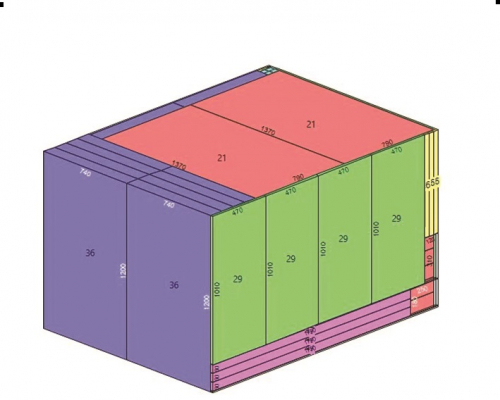

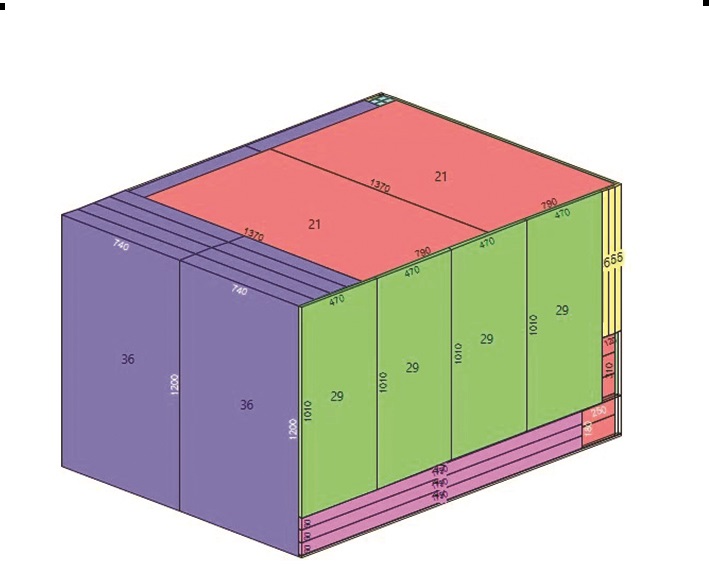

We need a program that optimizes the graphite cutting process to minimize waste. I would like to have access to a program created for our needs for optimal graphite cutting

Initial Problem Description

We buy graphite blocks that have different dimensions, are similar, but each delivery differs by a few millimeters in each area. Our customers buy different sizes and the problem is that large amounts of waste are generated. We would like to have a program that will allow me to give the dimensions, for example, 10 different dimensions, and the program will calculate how best to cut the block so that there is no waste.

Context

I bought a block of graphite with dimensions of 325 x640x640 mm. I have orders:

45x65x640 mm 10 pcs

55x65x640 mm 10 pcs

75x75x640 mm 5 pcs

105x105x640 mm 3 pcs

91x395x366 mm 1 pc

Each cut generates a few mm of waste, which must be taken into account in the cutting planning. How to arrange these dimensions to use as much material as possible and not generate waste, because then we do not make money on such waste and it remains in the environment as scrap

Connection to cross-cutting areas

My challenge is related to the area of digitalization, the need for a program created to develop optimal cutting without waste.I need a digital solution for my graphite block, which has a different size with each delivery and each order is unique. The program must include options so that it does not rely on standard dimensions, it must be flexible.

Input

Unfortunately, I don't have ready-made scriptsI believe that there are some products that will help optimize the graphite slicing process and a program that will help save waste

We buy graphite blocks that have different dimensions, are similar, but each delivery differs by a few millimeters in each area. Our customers buy different sizes and the problem is that large amounts of waste are generated. We would like to have a program that will allow me to give the dimensions, for example, 10 different dimensions, and the program will calculate how best to cut the block so that there is no waste.

Expectations

I expect an idea for a program that will enable economical commodity management for the company

We buy graphite blocks that have different dimensions, are similar, but each delivery differs by a few millimeters in each area. Our customers buy different sizes and the problem is that large amounts of waste are generated. We would like to have a program that will allow me to give the dimensions, for example, 10 different dimensions, and the program will calculate how best to cut the block so that there is no waste.

Desired Team Profile

The academic skills of the people in the team that is to develop a solution to my challenge are spatial imagination, mathematical and logical thinking, and a lot of ideas. People should know the rules of working in a group, together with others. ingenuity.....................................................................................................................................................................................................................................................................

Additional Information

I don't have such information about how the competition looks like how they deal with the problem of waste management and optimization of graphite cutting

We buy graphite blocks that have different dimensions, are similar, but each delivery differs by a few millimeters in each area. Our customers buy different sizes and the problem is that large amounts of waste are generated. We would like to have a program that will allow me to give the dimensions, for example, 10 different dimensions, and the program will calculate how best to cut the block so that there is no waste.

Related Keywords

About EDM TOOLS GROUP SP. Z O.O.

Our offer for you is mainly:

1. GRAPHITE ELECTRODES made on the CHMER HE65GT and OPS Ingersoll 600 machine guaranteeing accuracy.

2. GRAPHITES FOR EDM from two manufacturers:

– POCO – ultrafine graphites, dedicated to the aviation industry and high-precision electrodes; in addition, we offer advice on the technique and optimization of the drilling process,

– Tokai Carbon – a wide range of graphites for various applications.

3. EROWA AND FTOOL CLAMPING SYSTEMS to maintain a fixed base and quick changeover of machines.

4. CAD/CAM design services.

5. Cooperation in machining, EDM/WEDM drilling, deep hole drilling, grinding.

You need to sign up to apply to this challenge and submit a motivation letter!

Learn more about the topics and find team members!

Help

Need help submitting your proposal or have questions regarding this Open Innovation Challenge?

Contact support