Desired outcome

The challenge focuses on developing a strategic, actionable roadmap for Halmod to penetrate the modular hall construction markets in Eastern and Northern Europe. The key objectives are to address workforce shortages, leverage the advantages of modular construction, and adapt solutions to the specific needs and regulations of target countries such as Greece, Romania, Finland, and Sweden. Participants will explore innovative product features, market-specific adaptations, and strategies to position Halmod as a leader in the region while aligning with sustainability and digitalization trends.

The solution should include a clear value proposition, competitive analysis, and recommendations for market entry strategies. Teams are expected to showcase creativity, analytical rigor, and a deep understanding of the regional market dynamics. Halmod values impactful ideas and may consider future collaboration with participants who deliver exceptional results, offering opportunities for professional growth and involvement in the company’s business initiatives.

Initial Problem Description

The primary challenge is to explore and identify opportunities in the modular hall construction market across Eastern and Northern Europe (countries such as Greece, Bulgaria, Romania, Ukraine, Czech Republic, Slovakia, Hungary, Lithuania, Latvia, Estonia, Finland, Norway, and Sweden). The aim is to design a strategy to penetrate these markets effectively, considering specific barriers such as:

1) Workforce challenges: a shortage of skilled welders and high labor costs create the need for innovative, modular solutions that reduce the reliance on skilled labor.

2) Market adaptation: tailoring modular hall solutions to meet regional needs, considering differences in regulations, economic environments, and logistics capacities in each targeted country.

3) Competitor analysis: identifying competitors in these markets and determining the unique value proposition that modular halls from Halmod can offer to outcompete them.

4) Market entry strategy: developing a clear roadmap for entering and scaling operations in these countries, including identifying strategic partnerships, distribution networks, and pricing models.

The teams are tasked with addressing the above challenges by formulating innovative solutions that align with Halmod's strengths and the specific market characteristics of the targeted countries. They should also consider the potential for reducing entry barriers by leveraging modular hall advantages, such as ease of transport, assembly, and cost efficiency.

Context

The challenge arises in the context of rapidly expanding industrial, agricultural, and commercial markets in Eastern and Northern Europe. These regions exhibit a growing demand for versatile and cost-effective infrastructure solutions, such as modular halls, due to their adaptability and lower construction costs compared to traditional structures. Below is a broad overview of the problem context:

1) Economic landscape

Many countries in the targeted regions are experiencing industrial and agricultural growth but face challenges such as limited access to high-skill labor (e.g., welders) and constrained budgets for infrastructure projects.

Modular construction offers an affordable, scalable solution for businesses in these areas, particularly SMEs, to quickly adapt to market demands.

2) Labor shortage

A significant shortage of skilled welders and high labor costs in construction create a barrier to traditional building methods.

Modular halls, which rely on pre-fabricated, easily assembled components, address this gap by minimizing the need for on-site welding and other specialized skills.

3) Diverse use cases

- modular halls serve various purposes, including:

* industrial applications: warehousing, manufacturing plants, and logistics centers.

* agricultural needs: storage for machinery, crops, and livestock.

* commercial spaces: Retail spaces, event halls, and sports facilities.

These use cases vary significantly across countries, requiring tailored solutions to meet local needs.

4) Regional challenges

- infrastructure and logistics: Some regions, particularly in Eastern Europe, have limited transport and logistics infrastructure, posing challenges for delivering modular components.

- regulatory hurdles: construction and zoning regulations differ between countries and regions, necessitating localized adaptation of products and processes.

- climate considerations: northern countries such as Finland, Norway, and Sweden require structures that withstand extreme weather conditions, while Southern regions like Greece prioritize heat-resistant designs.

5) Competitive Landscape

- established local and regional competitors already operate in the modular hall market, offering similar products.

- identifying Halmod’s unique value proposition, such as innovative design, cost efficiency, or faster assembly, will be critical to outcompeting these players.

This problem is situated at the intersection of construction innovation, workforce trends, and market adaptation, making it a multidisciplinary challenge requiring insights from business, engineering, and cultural understanding. The action plan will be concretized during a kick-off meeting with students.

Connection to cross-cutting areas

The challenge connects to the following cross-cutting areas:

1) Circularity

- reusability of modular components: modular halls align with circular economy principles by allowing for disassembly, relocation, and reassembly, reducing construction waste.

- material efficiency: optimizing designs to use materials efficiently ensures minimal waste during manufacturing and installation.

- recycling: promoting the use of recyclable materials (e.g., steel, aluminum) for the modular components enhances sustainability and reduces the environmental footprint.

2) General sustainability

- lower carbon footprint: prefabrication and streamlined logistics reduce emissions compared to traditional construction methods that require extensive on-site work.

- energy-efficient designs: modular halls can incorporate features like insulation and energy-efficient materials to reduce heating or cooling requirements, especially in climates of Northern and Eastern Europe.

Sustainable Supply Chains: sourcing materials locally and optimizing transportation reduce environmental impacts and promote regional economic growth.

3. Industry 4.0

- advanced manufacturing: leveraging Industry 4.0 technologies such as automation, 3D printing, and IoT-enabled monitoring can enhance production efficiency and quality control of modular components.

- smart modular halls: Incorporating sensors and IoT devices into modular hall designs can allow for real-time monitoring of structural integrity, energy usage, and environmental conditions, improving operational efficiency and lifespan.

- data-driven optimization: utilizing data analytics to optimize design, production, and logistics processes for modular hall construction.

4. Digitalisation

- digital twins: creating digital replicas of modular hall designs allows for precise simulation, customization, and troubleshooting before production begins.

- online marketplaces and customization platforms: developing digital platforms for clients to customize modular hall designs and receive instant pricing and delivery estimates enhances customer experience.

- supply chain management: digital tools can improve inventory management, component tracking, and delivery scheduling, ensuring efficiency in logistics and operations.

By integrating these areas, the challenge not only addresses market needs but also contributes to broader goals of sustainability, innovation, and digital transformation in the construction industry.

Input

The challenge is shaped by key scenarios and known trends in the modular construction industry, particularly across Eastern and Northern Europe. A significant shortage of skilled labor, such as welders, has heightened the appeal of modular solutions that simplify on-site assembly. This trend aligns with the growing demand for fast, scalable infrastructure in industrial, agricultural, and logistical sectors in regions like Romania, Lithuania, and Sweden. Modular halls present an opportunity to address these workforce challenges while providing cost-effective, quickly deployable infrastructure solutions tailored to local market needs.

Additionally, sustainability and digital transformation are reshaping construction practices globally. Modular designs that incorporate circular economy principles, such as reusability, recycling, and minimal waste, are increasingly favored by environmentally conscious governments and businesses. Furthermore, integrating digital tools like Building Information Modeling (BIM) and IoT technology enhances the functionality and efficiency of modular halls, appealing to markets that prioritize innovation and compliance with sustainability mandates. For example, energy-efficient designs and smart monitoring systems are particularly relevant in colder climates like Finland and Norway.

Finally, the competitive landscape and logistics trends present opportunities for differentiation. Many existing players in the modular hall market cater to traditional demands but lack innovative features such as ease of assembly, smart technology, or eco-friendly materials. By emphasizing unique value propositions—such as rapid deployment, cost-efficiency, and adaptability to diverse climates—Halmod can address specific use cases. These include scalable warehousing solutions for Romanian logistics firms, climate-controlled agricultural storage for Lithuanian cooperatives, and eco-friendly retail spaces for Finnish businesses.

Expectations

Expectations

We expect the solution to evolve towards a strategic, actionable roadmap for market entry into Eastern and Northern Europe, tailored to the modular hall industry. The solution should focus on addressing workforce challenges, leveraging modular construction advantages, and aligning with regional market needs. It should provide innovative ideas for product differentiation, such as features emphasizing sustainability, circularity, and digital integration. Additionally, the solution should outline a clear value proposition that positions Halmod as a leader in these markets while considering logistical, regulatory, and cultural nuances.

Beyond the final solution, we expect the team to demonstrate a strong analytical approach and teamwork throughout the process. This includes conducting thorough research, applying relevant tools like SWOT analysis or competitor benchmarking, and justifying their recommendations with data and market insights. Creativity and critical thinking will be crucial in designing solutions that not only solve the problem but also anticipate potential barriers and propose strategies to overcome them.

Desired Team Profile

A strong business and marketing foundation is essential for the team solving this challenge, as the success of the solution heavily depends on a well-designed market entry strategy. Team members with expertise in market analysis, strategic planning, and business development will bring valuable insights into understanding the competitive landscape and identifying unique opportunities in Eastern and Northern Europe. Their knowledge of pricing strategies, customer segmentation, and regional market dynamics will be critical for tailoring the modular hall solutions to meet the diverse needs of industries such as logistics, agriculture, and manufacturing in these regions.

Additionally, business and marketing experts can ensure the proposed solutions are not only feasible but also align with Halmod’s long-term goals for market leadership. They will contribute to crafting a compelling value proposition that highlights the advantages of modular construction, such as cost-efficiency, sustainability, and adaptability. Their ability to translate technical and sustainability features into tangible customer benefits will play a key role in developing impactful marketing strategies and building brand recognition in these new markets.

Additional Information

The detailed plan and scope of the challenge will be discussed and refined after selecting the student group, ensuring the tasks and expectations are clearly aligned with the team's capabilities and expertise. This collaborative approach will allow the students to better understand the company's vision and priorities, while also giving them the opportunity to tailor their efforts to the most pressing market needs and challenges. Guidance, feedback, and access to relevant resources will be provided throughout the process to support the team in achieving meaningful outcomes.

Moreover, Halmod values innovation and collaboration, and in the case of exceptional results, the company does not exclude the possibility of involving participants in future business endeavors. Outstanding contributions could pave the way for internships, project-based partnerships, or even employment opportunities, offering students the chance to further develop their ideas and share in the benefits of the business initiatives they help create. This challenge is not only a learning experience but also a potential stepping stone for a closer professional relationship with the company.

Related Keywords

About HALMOD GROUP SPÓŁKA Z OGRANICZONĄ ODPOWIEDZIALNOŚCIĄ

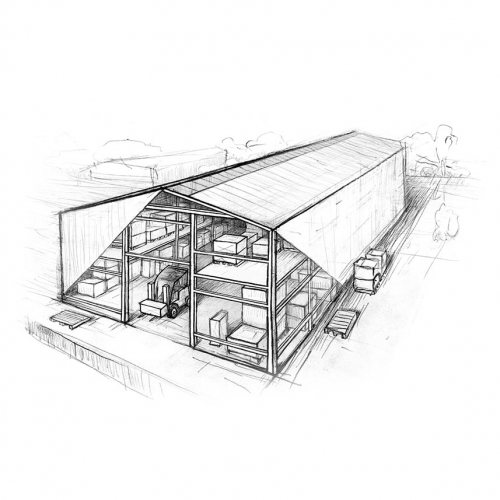

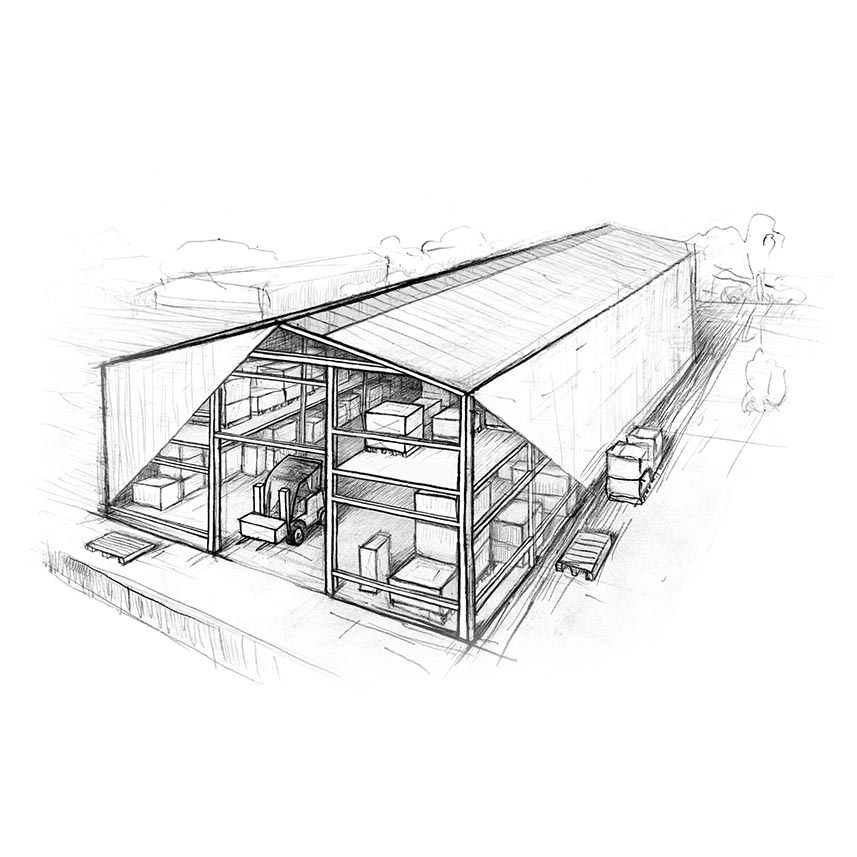

HalMod Group specializes in manufacturing modern, robust steel halls using a modular system. Their offerings include both standard modular constructions and customized solutions starting from 400 m². The modular technology allows for easy expansion, enabling facilities to grow alongside clients' needs. HalMod provides comprehensive services, including hall design and handling all necessary documentation. Clients have the option for self-assembly or professional installation by HalMod's team. The company utilizes high-quality cold-formed structural steel (S355JR) and hot-dip galvanized sheet (S350GD+Z) with additional ribbing to ensure structural stability. Their steel halls are versatile, suitable for various industries, and can be easily customized with commercially available doors, gates, windows, skylights, cladding, sandwich panels, and trapezoidal sheets. The modular design facilitates quick and straightforward installation, with all components marked and numbered for ease of assembly. Additionally, the structures are designed and manufactured according to applicable standards, including ISO 9001:2015, ensuring safety and reliability.

You need to sign up to apply to this challenge and submit a motivation letter!

Learn more about the topics and find team members!

Help

Need help submitting your proposal or have questions regarding this Open Innovation Challenge?

Contact support