- PIW Delta Sp. z o.o.

- Responsive

- Posted by

Desired outcome

The varnish is to be used for fire-resistant and decorative protection/finishing of building elements made of wood and wood-based materials (chipboard, plywood, OSB boards, etc.), used inside rooms in residential and public buildings, as well as outside buildings. After application to the substrate and drying, it is to create a transparent, colorless coating, without changing the color of the wood. Under the influence of high temperature, the coating swells, creating a foamed insulating layer. Fire efficiency should be at the level of: class B–s1, d0 reaction to fire, which corresponds to the classification: non-flammable, non-dripping, non-falling off under the influence of fire and non-spreading fire through walls when exposed to fire inside the building.

Initial Problem Description

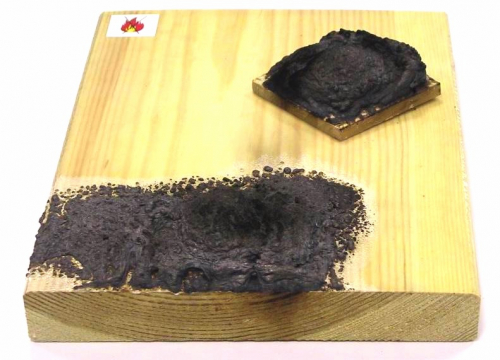

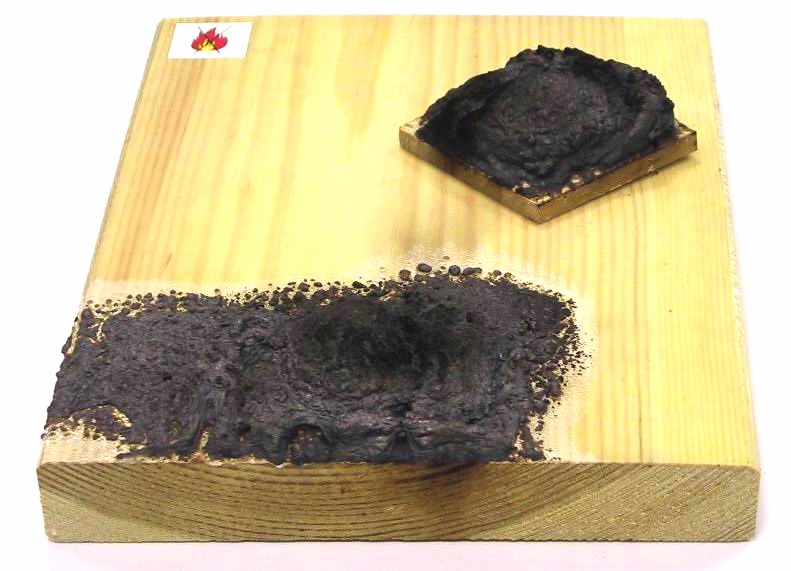

Our challenge is to develop a formula for a fire-retardant, swelling varnish for wooden materials that can be used inside and outside buildings. The varnish should have a protective and decorative function. After being applied to the substrate and drying, it should create a transparent, colorless coating that will swell under the influence of high temperature, creating a foamed insulating layer. The varnish should have a fire classification of class B–s1, d0. Such high fire efficiency is provided by swelling varnishes, which, after contact with fire, create a swollen carbon layer that blocks fire from reaching the wood. It is important to create a varnish base that will make the product resistant to weather conditions.

Context

The use of intumescent coatings is one of the most effective methods of protecting flammable materials from the effects of fire. Under the influence of fire, they create a layer that insulates the surface from the effects of high temperature. Under the influence of temperature, the coating becomes plastic and releases chemically inert gases. These gases cause the coating to transform into a porous layer 30-50 times thicker than the initial thickness. The soft, semi-liquid layer chars and solidifies. The mechanism of action of intumescent coatings in the combustion process consists of several stages. In the first stage, the dehydrating agent decomposes with the release of acid from its ammonium salt or ester. The resulting acid reacts with the component providing carbon, and esterification of the hydroxyl groups of the charring substance occurs in the presence of a suitable catalyst. With a further increase in temperature, the esters decompose with the formation of carbon, free acid, water and carbon dioxide. The resulting acid reacts again with the hydroxyl groups of the charring substance and, in parallel with the decomposition of the ester, the decomposition of the pore-forming agent occurs, which results in a thick porous insulating layer. The resulting foamed porous layer perfectly isolates the access of both heat and oxygen, thus protecting the protected material from the effects of fire.

Connection to cross-cutting areas

The development of a fire retardant paint formulation can be linked to any of the areas mentioned – Circular, overall sustainability, Industry 4.0 and digitalisation – depending on the approach and design priorities. The strongest link, however, seems to be to overall sustainability, although other areas are also relevant. Let’s take a closer look at this by choosing one area and expanding on it – I will focus on sustainability because it seems to be the most universal in this context, but I can adjust the answer if you point to another area.

Input

We count on cooperation based on direct contact (including e-mail, telephone), consisting of transferring all information that the company has in the area of fire protection agents. We also have the knowledge of our best specialists-professors (world rank) in the field of fire protection products, with whom consultation is possible.

Expectations

We expect to create a recipe for a fire-resistant swelling varnish for wooden materials, which can be used inside and outside buildings. The varnish should have a fire classification of class B–s1, d0. Such high fire efficiency is provided by swelling varnishes, which, after contact with fire, create a swollen carbon layer that blocks fire from reaching the wood. It is important to create such a varnish base that the product is resistant to weather conditions.

Desired Team Profile

The development of fire retardant paint formulations should be handled by an industrial chemistry specialist or chemical engineer, preferably with experience in the field of fire retardant materials and protective coatings. Such an expert should have knowledge of:

Polymer chemistry – because fire retardant paints are often based on special resins and additives that react at high temperatures to form an insulating layer.

Materials technology – to understand how the paint ingredients affect its physical and chemical properties, e.g. fire resistance, adhesion to the substrate or durability.

Fire safety standards and regulations – such as the European EN 13501 standard or national regulations that specify requirements for fire retardant paints.

Often in practice, such a person may also be a paint and varnish technologist working in the research and development (R&D) department of a company producing protective coatings. Cooperation with fire engineers or fire protection specialists can also be crucial to adapt the formulations to specific applications, e.g. in construction or industry.

Additional Information

An example of a competitive product is the Uniepal Drew Special FR Fire-Retardant Varnish. The use of intumescent coatings is one of the most effective ways of protecting flammable materials from the effects of fire. During a fire, coatings of this type swell into a thick, foamed layer with a highly porous structure, which insulates the protected surface from excessive heating, and consequently from losing its strength.

The basic ingredients of intumescent paints are:

- film-forming base,

- carbon-supplying component - an agent creating a charred layer,

- catalyst - dehydrating agent,

- flame retardant - blowing agent (foaming agent).

The basic ingredients of fire-retardant paints listed above cannot be selected arbitrarily. Thermal decomposition of individual paint components must occur in a specific order. The dehydrating agent (dehydration catalyst) must decompose at a temperature close to the decomposition temperature of the blowing agent. If the decomposition temperature of the blowing agent is significantly higher than the decomposition temperature of the catalyst, an unswollen charred layer will be formed, which does not have a spongy structure and therefore does not exhibit low thermal conductivity. However, if the decomposition temperature of the blowing agent is too low, the gases are released before the charred layer is formed. Compounds with self-swelling properties have also been developed. They simultaneously act as a source of carbonaceous matter and a blowing agent. These include nitroaniline sulfate and sulfanilimides. Nitroaniline sulfate swells as a result of an exothermic reaction, and is therefore not suitable for fire-resistant coatings. The swelling reaction of sulfanilimides is endothermic, but the foam produced has worse insulating properties and fire resistance than the foam formed as a result of the interaction of the three traditional components of intumescent coatings discussed above.

Related Keywords

About PIW Delta Sp. z o.o.

Delta Innovation and Implementation Company specializes in the production of chemicals for vulcanization, health and safety products, fire protection products, including intumescent varnishes and specialist products for gardening. One of the foundations of the company's strategy is investing in the continuous development of the products offered. Our company participates in the implementation of research and development projects conducted in cooperation with university centers and other organizations supporting the development of Polish science. Thanks to the joint implementation of projects, we actively participate in the exchange of knowledge and experience between the chemical industry and the science and higher education sector. These activities resulted in the expansion of the company's offer with products with a very high level of innovation, such as dendrimeric polymers. The company has a production plant in Dolsk, employs 7 people.

You need to sign up to apply to this challenge and submit a motivation letter!

Learn more about the topics and find team members!

Help

Need help submitting your proposal or have questions regarding this Open Innovation Challenge?

Contact support